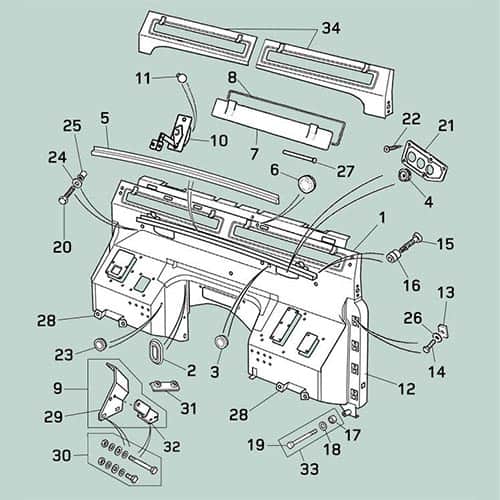

Description

Land Rover Defender Bulkhead galvanised

Made from the latest Land Rover Galvaneal galvanized metal then electrostatic e-coat primed for superior corrosion resistance. This is an exact replacement for all 1995 NAS 90 models that will easily adapt to fit NAS 1994 Soft tops. Supplied with air vent flaps fitted. Requires upgrading to the latest wiper wheel boxes offering improved wiper arm performance. Supplied ready for paint.

Land Rover Defender Bulkhead 90 110

Our Land Rover Defender bulkheads are built by hand, to exact specifications, by experienced fabricators with over 28 years experience. Each bulkhead is manufactured from new 1.6mm mild steel and is hot-dip galvanised for ultimate protection. Extraordinary care has been taken to match each curve and contour.

Availability: In Stock – Next Day Turkey Delivery or Collection.

Manufactured from new 1.6mm mild steel.

Hot-dip galvanised and sealed.

Includes model specific features.

Jigs are used to securely hold and accurately space all components as each bulkhead is assembled.

Our bulkheads are manufactured in the UK, with British materials, and offer the best quality available.

Next Day UK Delivery, Collection or Worldwide shipping available.

Additional options

Available in RHD (right hand drive) or LHD (left hand drive) configuration.

We offer a ready to paint primer coating for an additional charge.

We offer RAPTOR® coating for an additional charge.

The bulkhead manufacturing process

The first step is to take new flat de-coiled mild steel sheets and cut them to length.

Next, using a CNC laser cutter, all of the components are carefully cut to a flat profile.

Then, the required parts are folded out and pressed into the components using a specially formed die. During this process the sub-assemblies are also manufactured.

Once the bulkheads are fully assembled and jigged they are sent off to be hot-dip galvanised and then sealed.

Finally, after galvanising we re-jig each bulkhead for quality control, before carefully packaging them ready to be dispatched.

Our hot-dip galvanised coating

Hot-dip galvanising provides a number of benefits to the steel it protects. The metallurgically-bonded zinc-iron alloy layers not only create a barrier between the steel and the environment, but also catholically protect the steel. The cathodic protection offered by zinc means the galvanised coating sacrifices itself to protect the underlying base steel from corrosion.

The tightly adhered coating, which has bond strength of around 3,600 psi, is also extremely abrasion-resistant, as the inter-metallic layers are harder than the base steel. However, even if the coating is damaged, zincs sacrificial action will protect exposed steel up to ¼ inch away.

Hot-dip galvanising is the process of coating iron or steel with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 842 °F (450 °C). During the process, a metallurgically bonded coating is formed which protects the steel from harsh environments, whether they be external or internal. Galvanised steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel and can be identified by the crystallised pattern on the surface (often called a ‘spangle’). Galvanising is probably the most environmentally friendly process available to prevent corrosion.

Prices vary depending on the destination country, the quantity to be purchased, and the current exchange rate in Turkey.

Please provide these details when requesting a price.